What is a geological drill pipe?

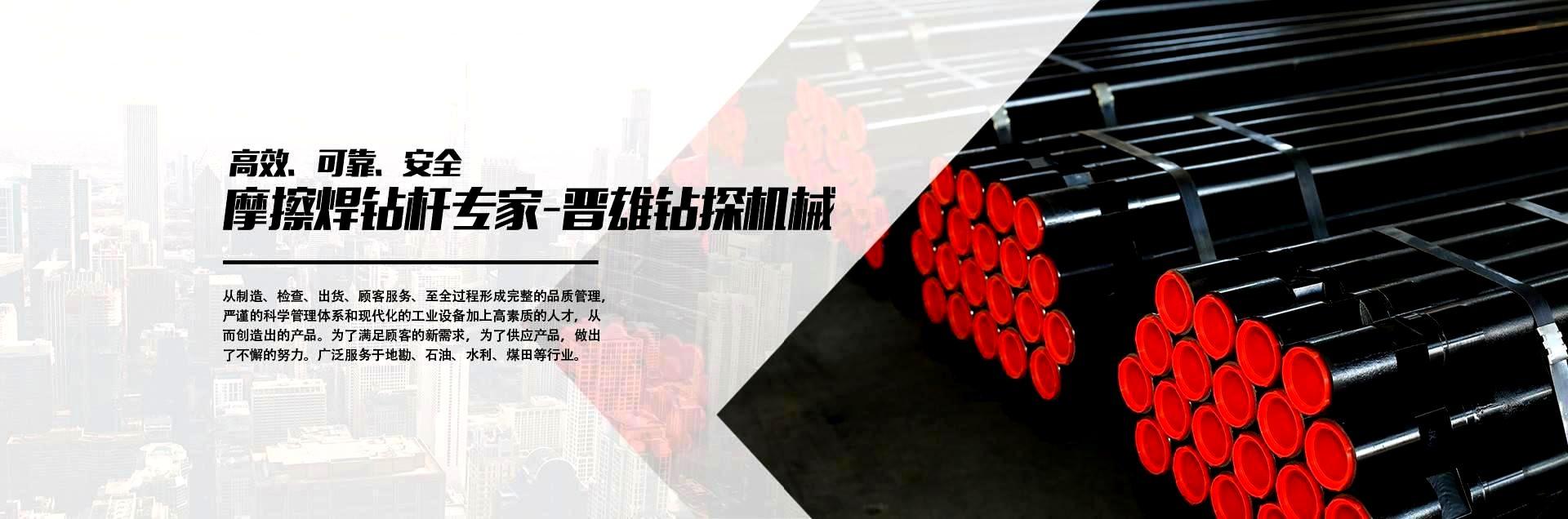

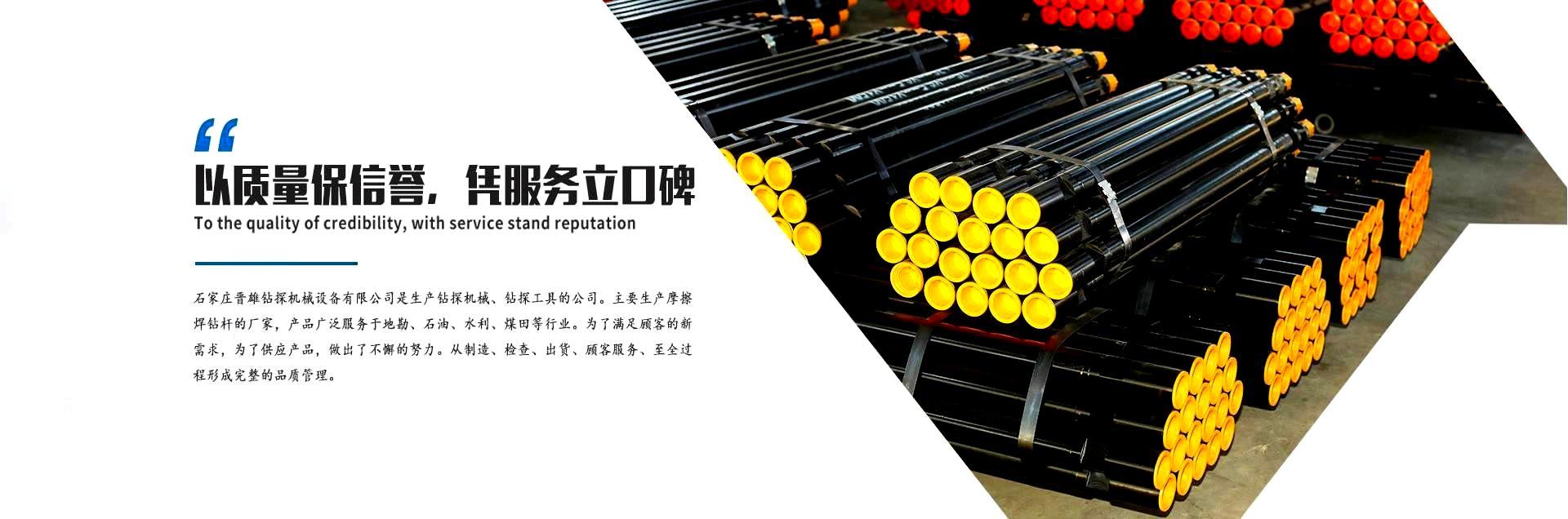

Geological drill pipe is a kind of geological drilling tool which is planned and consumed by friction welding process with geological alloy steel pipe. Geological drilling rod: a geological drilling tool that is planned and consumed by friction welding process of geological alloy steel pipe. Material: Geological drill pipe shaft is made of special alloy steel pipes (R780, DZ50), and geological drill bit is made of high-quality alloy structural steel (42CrMo), which has greatly improved the fatigue strength and shear strength. Consumption technology: advanced friction welding technology is selected for consumption processing. The drill pipe has the characteristics of high bending strength and firm welding, which can ensure the requirement of straightness during deep hole drilling, and has high fatigue strength and long service life. Common specifications: Φ34*1m, Φ42*1m, Φ50*1m, Φ60*1m, Φ63.5*1m, Φ73*1m. Common connection methods: male-female connection (tapered thread) and joint connection (rectangular internal thread) Rusting is a very common problem in the construction of drill pipes. Rusting of drill pipe will greatly shorten its life. Therefore, in operation, it is not only important to pay attention to the correct application method, but also important to the maintenance after construction and the rust prevention method of drill pipe. 1. The builder can choose a suitable rust remover according to the types, surface conditions, dimensional accuracy and surface quality of geological drill pipes. Perhaps the use of chemicals, the application of chemical reaction to dissolve the corrosion products on the metal surface of the pickling method. Its principle is the dissolution of metal by acid and the mechanical effect of hydrogen generated in chemical reaction on rust layer. Commonly used acids include hydrochloric acid, sulfuric acid, phosphoric acid, etc. 2. Stop coating anticorrosion in professional factories, and ensure the construction quality; 3. Phenolic resin modified epoxy resin coatings and epoxy polyurethane coatings are very useful for corrosion protection of drill pipes.

ch

ch

English

English

18931984404

18931984404

二维码

二维码