Why do most drilling construction teams choose friction welding drill pipes?

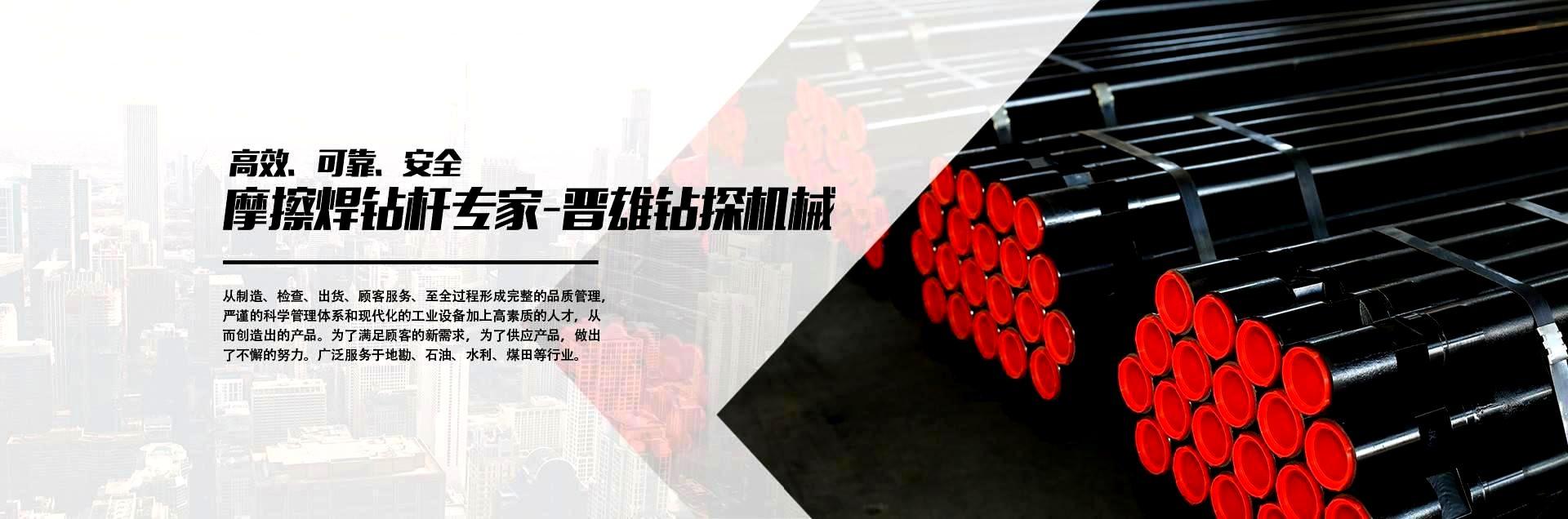

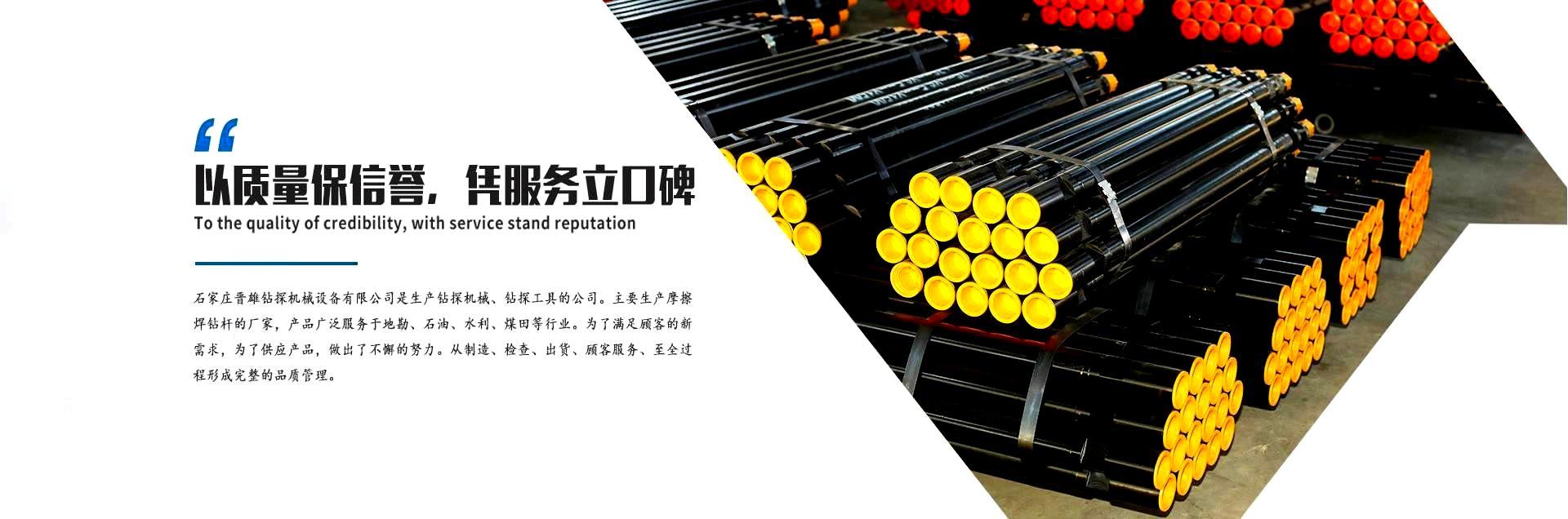

It is because the friction welding drill pipe is relatively simple to operate, and one of them is a grooved drill pipe, which is basically in the form of double helix, which is a complicated structure. In addition, the geological alloy steel pipe with comparative advantages is selected, which has a strengthening effect, can effectively improve the wear resistance to a certain extent, can effectively avoid wear, and will not easily affect the normal service life, thus achieving a replaceable role. There are no seasons when friction welding drill pipes are used, but if they are used in winter, they should be maintained regularly first. After all, the humidity of air and the change of environment will affect the quality of products invisibly. During the maintenance process, it is suggested that dust-proof treatment and antirust oil treatment should be carried out on a regular basis in combination with the humidity of the air and the environment. In addition, it is necessary to ensure that the drill pipes can be closely connected in a ventilated state, and it will take time to replace the sealing ring in case of wear or damage. There are some similarities between the use of friction welding drill pipe and diamond drill bit. First, we must choose a special drilling pipe, which is welded with the joint after friction, and has good follow-up, and the tensile strength is compared, which can adapt to some conventional drilling processes. In addition, even if it is used in some special environments, the address change can also be easily completed, but it needs to be used in the process of use, otherwise it will easily lead to sudden death and seizure, which will lead to bending and deformation of the rotating rod.

ch

ch

English

English

18931984404

18931984404

二维码

二维码